Our 300 kW hydrogen fuel cell is built on over 25 years of research and development conducted at the CEA (the CEA is a French research center specialized in energy technologies, particularly low-carbon energy systems, batteries, hydrogen, and energy efficiency. It focuses on applied research to support the energy transition and industrial innovation.). It incorporates 15 patents covering both hardware and software, ensuring precise control of performance, efficiency, and durability.

The system is based on the high-performance Z300 stack, capable of delivering over 300 kW with high power density and fast transient response, reducing the need for large-capacity auxiliary batteries

Our 300 kW hydrogen fuel cell is built on over twenty-five years of research and development conducted at the CEA. It incorporates fifteen patents covering both hardware and software, ensuring precise control of performance, efficiency, and durability. The system is based on the high-performance Z300 stack, capable of delivering over 300 kW with high power density and fast transient response, reducing the need for large-capacity auxiliary batteries

A fuel cell directly converts the chemical energy of hydrogen into electrical energy. It consists of a bipolar plate, which distributes the gases and collects the current, and an MEA (Membrane Electrode Assembly), made of an electrolyte membrane sandwiched between catalytic layers of the anode and cathode.

Hydrogen reaches the anode, where the catalyst separates the molecules into protons and electrons. The membrane only allows protons to pass through to the cathode. The electrons, however, cannot cross the membrane and are forced to flow through an external circuit, thereby generating electric current and heat.

At the cathode, protons, electrons, and oxygen from the air combine to produce water as the only by-product. This process enables continuous, emission-free power generation.

The INOCEL Z300-S is a fuel cell system designed for stationary applications. It provides clean and continuous energy where reliability is essential.

This system is integrated directly into our generators, offering a ready-to-use solution to produce electricity without emissions. The Z300-S is intended for a variety of applications, such as industrial sites, critical infrastructures, or any environment requiring a stable and durable power supply.

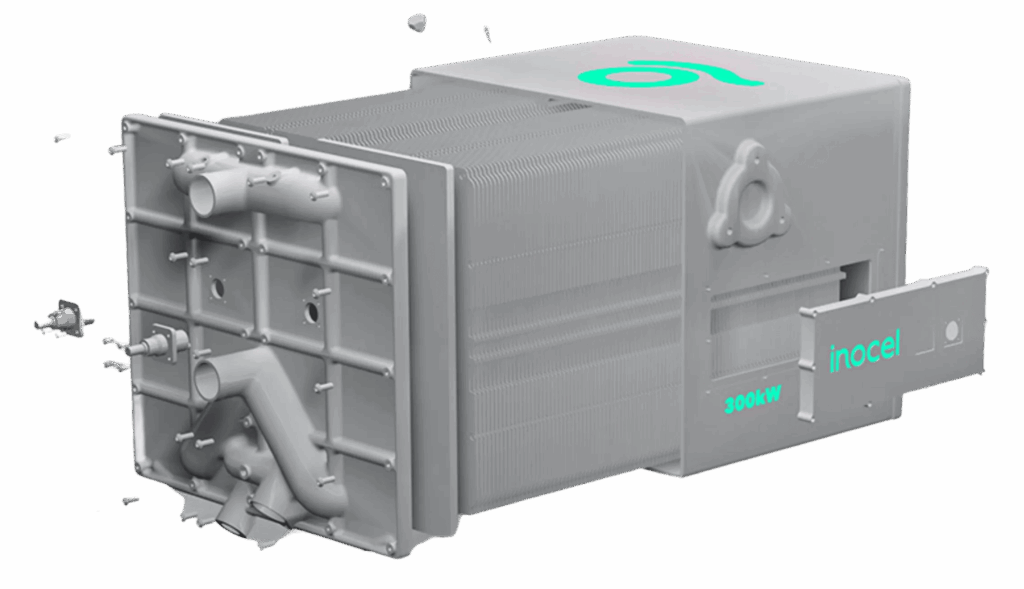

The system surrounding the stack includes the stack, air and hydrogen ducts, control elements, and intelligent software to ensure optimal performance.

The system surrounding the fuel cell, known as the stack, plays a key role in the overall performance of our product. It is a complete system that integrates a stack, an air supply, a hydrogen supply, a ducting system, and control elements. This complete system, powered by intelligent software, delivers unmatched performance to our customers.

Power

>300 kW

Efficiency

up to 65%

Dimensions

440x450x491mm

Weight

136 kg

Volume

97 l

Power ramp-up

<2 s

At equivalent volume and weight, INOCEL fuel cells deliver up to three times more power than market standards, offering simpler and more flexible integration.

With an efficiency of up to 60%, INOCEL systems convert more energy into useful electricity, while ensuring reliability, longevity, and reduced operating costs.

The Z300 fuel cell reaches its maximum power in less than 1.5 seconds, minimizing the need for batteries and enabling instant primary power production.

Thanks to a modular architecture and intelligent control software, INOCEL systems can scale from 300 kW to several MW, precisely adapting to each energy requirement.

The INOCEL software continuously optimizes the performance, efficiency, and lifespan of the fuel cell, while enabling precise monitoring and predictive maintenance.

Thank you for your interest. Your datasheet download is ready.

Thank you for your interest. We will get back to you soon!